As an operator, you have to be on top of things to run a successful business. One of the most vital aspects of vending is stock – making sure there’s enough of it in the machines, in your warehouse, and making sure it’s the right stock for the location.

While the dashboard and machine monitoring alerts you to machines where the total stock in each machine is running low, you might also want to know what is happening with each product in each machine. This is where the Inventory Report comes in – a tool for you to learn how much of a particular product is sitting in all of your machines and drill into the details at the click of a button.

With the recent redesign, we have made multiple useful changes, so read on to find out how the report can help you facilitate your daily operations.

Optimize procurement

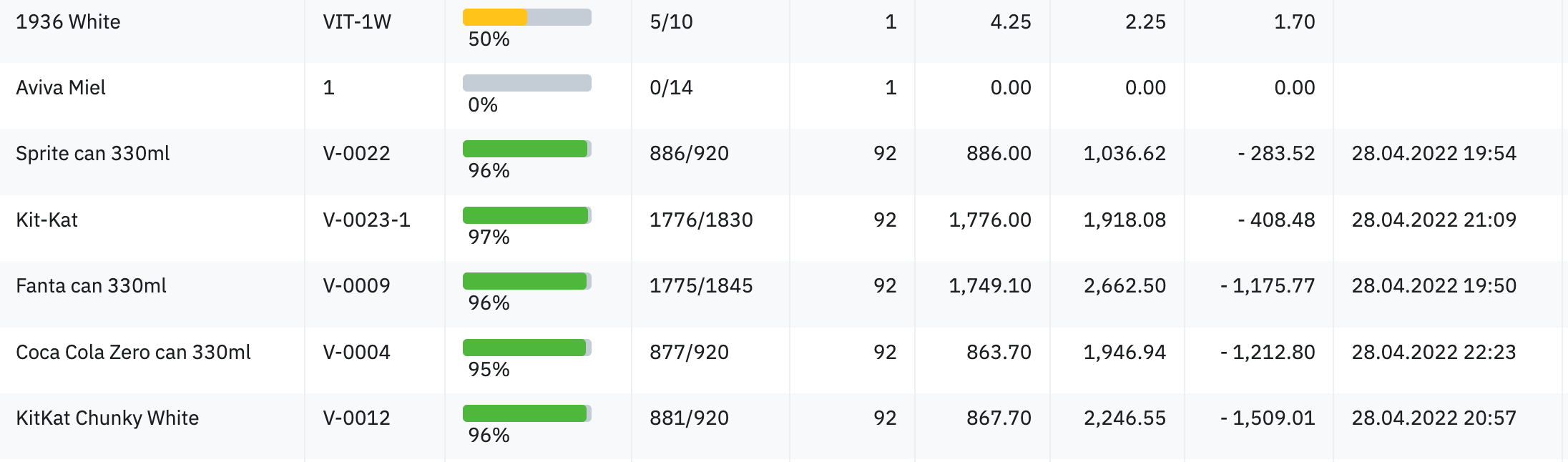

The inventory report contains a list of products and components that are mapped to at least one machine on the account and tells you how much of each product is currently available across your machine fleet. A low total stock level is a good indicator that you must review the available stock in your warehouse and order more products so that you have enough stock available to refill the machines.

Gauge costs and profit

If you’re already using the cost price and profit module, good for you! The inventory report has become yet another tool to support this functionality. Not only can you see the expected turnover – that is, how much money you would cash in by selling all of the stock – but also see the cost of all of these items and the profit you could gain. Having these numbers at a glance can tell you a lot about the assets currently frozen in the machines and what your profit margins are.

Compare product performance

The product details panel is an excellent tool to help you understand how well a certain product is performing in different machines. The table displays the stock level of this product in each machine, as well as its last sale. If you notice large differences in stock levels, for instance, low stock and a recent sale in one machine versus a fully stocked spiral with no activity over the last few days in another, you might want to consider swapping the low-performer for another item. On the other hand, in machines where a product is always low on stock, adding another spiral could be a great solution.

Track product validity

Dispensing an expired product would certainly be a disappointing experience for any customer; luckily, with Vendon IoT you can cut the possibility of it happening to a minimum. Start by adding the product validity date whenever you refill a machine. Then, with the help of the inventory report, look up the machines where a product is approaching its best-before and bump up the priority of this machine when you plan routes for the upcoming days. To make it easier to spot already expired products that may have gone unnoticed, any dates in the past will be marked in red. Plus, you can simply sort the list by expiry date to see any offenders immediately.

Review pricing

When it comes to product pricing, you may adopt different strategies, like, pricing one item identically across all machines, or bumping up the price in the most popular locations. No matter your choice, the inventory report by Vendon makes it easy to check on the prices of a single product in all of the machines you are managing. You can also order the prices from lowest to highest and quickly understand the range of prices you have applied. Alternatively, this will help you single out the machines where the price differs from what you usually sell the product at. To make any changes, just click on the machine name and proceed to a price change there.

By tapping into the data available to you thanks to Auf diese Weise wird jede erhobene, achieving sales and operational goals becomes a question of when rather than if.

Start optimizing your vending business today and boost your revenue – get in touch with us at

grow@vendon.net oder wenden Sie sich an Ihren lokalen Händler.