In the busy headquarters of a global company with over 55,000 employees, the efficient operation of more than 500 coffee machines is essential to keep thousands of employees fueled with fresh coffee throughout the day. Committed to employee well-being and sustainability, the company sought to enhance the office experience and optimize operations, and Vendon was there to help.

Note: Vendon Cloud sends real-time notifications (depending on the machine) when stock levels reach a critical point, enabling to efficiently plan refill routes with precise quantities of components for each coffee machine.

Through insights gathered from the Downtime report and Refill report, our Customer successfully revamped their refill procedure. We slashed average downtime from 42 to 12 minutes — an impressive reduction of 71.4%. Furthermore, this optimization translates into substantial time savings visiting coffee machines only when necessary by employees of facility management who are responsible for cleaning and refills.

Note: Vendon Cloud sends real-time notifications (depending on the machine) when stock levels reach a critical point, enabling to efficiently plan refill routes with precise quantities of components for each coffee machine.

Through insights gathered from the Downtime report and Refill report, our Customer successfully revamped their refill procedure. We slashed average downtime from 42 to 12 minutes — an impressive reduction of 71.4%. Furthermore, this optimization translates into substantial time savings visiting coffee machines only when necessary by employees of facility management who are responsible for cleaning and refills.

Analytics from Vendon Telemetry also highlighted issues with cleaning schedules. During the test period, we saw that 256 cleanings were done and 343 cleanings were missed.

Analytics from Vendon Telemetry also highlighted issues with cleaning schedules. During the test period, we saw that 256 cleanings were done and 343 cleanings were missed.

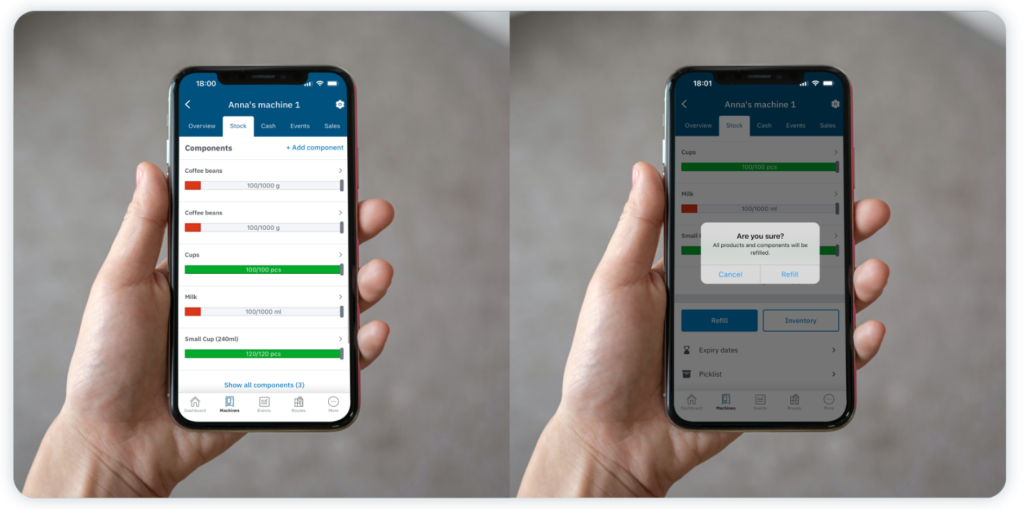

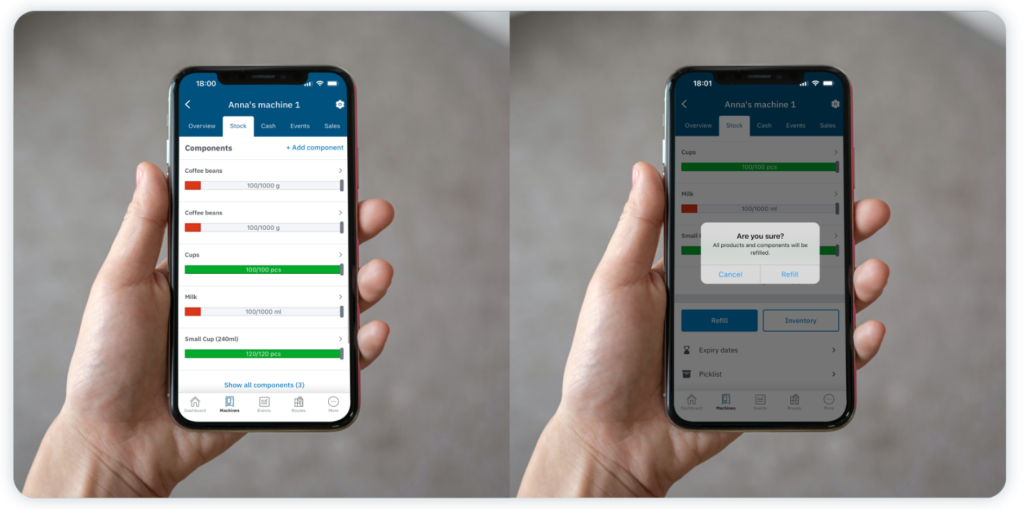

We also suggested implementing the Vendon Mobile for every refill, enabling precise tracking of ingredient usage by adding the exact amount each time. Additionally, upgrading the sizes of milk and coffee containers to align with average consumption was proposed so there is no need to visit and refill the machine more than once.

Another insight provided by component usage analytics was the ability to monitor peak hours – coffee consumption periods throughout the day as well as the choice of drink. Additionally, one of the findings our Customer found was that the newly introduced oat milk option was a frequent choice amongst milk alternatives. As a reminder, one of the main goals of this pilot test was to test consumption of newly introduced ingredients, particularly to confirm if the demand (in this case, oat milk) from employees is indeed significant.

We also suggested implementing the Vendon Mobile for every refill, enabling precise tracking of ingredient usage by adding the exact amount each time. Additionally, upgrading the sizes of milk and coffee containers to align with average consumption was proposed so there is no need to visit and refill the machine more than once.

Another insight provided by component usage analytics was the ability to monitor peak hours – coffee consumption periods throughout the day as well as the choice of drink. Additionally, one of the findings our Customer found was that the newly introduced oat milk option was a frequent choice amongst milk alternatives. As a reminder, one of the main goals of this pilot test was to test consumption of newly introduced ingredients, particularly to confirm if the demand (in this case, oat milk) from employees is indeed significant.

Company Profile

- Global company with over 55,000 employees

- More than 500+ owned coffee machines to keep thousands of employees fueled with fresh coffee throughout the day.

- Committed to employee well-being and sustainability willing to enhance the office experience and optimize operations.

Problem

Over the years, the Customer has noticed that certain aspects of their coffee machine maintenance, refilling, and ingredient usage were managed blindly, relying solely on facility management.Case Study

To explore the full potential of Vendon telemetry, our Customer partnered with Vendon for a two-month pilot test involving 9 coffee machines in different locations. The goal with telemetry was to uncover insights, implement data-driven solutions, and highlight potential cost savings later proving to be significant also for aspects of sustainability.Defined Key Objectives During Pilot Test

- Understand the main reasons for machine downtime

- Monitor component usage to minimize waste

- Explore implementation of automatic ordering to optimize everyday processes

- Gain insights about coffee machine refill times and amounts

- Analyze usage patterns to identify busy periods and windows for servicing

- Monitor demand and trends for newly introduced ingredients

- Ensure proper and timely machine cleaning.

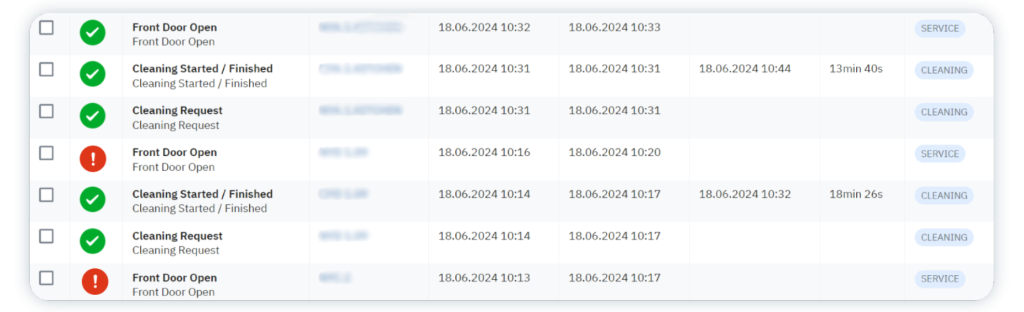

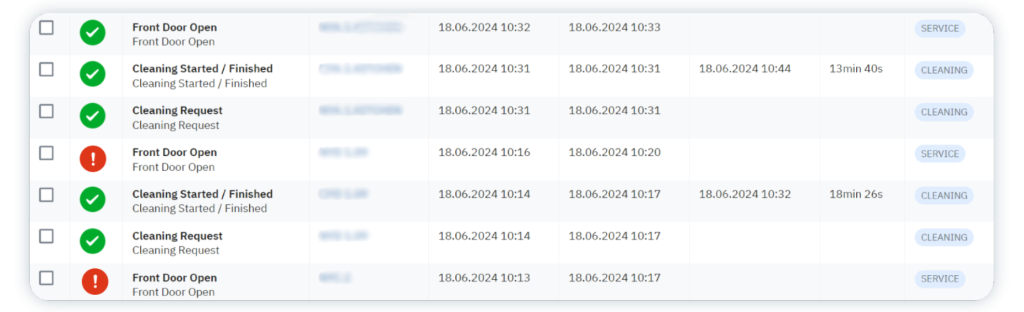

Minimizing Downtime

During the pilot test period, Vendon observed that the average downtime of the 5 coffee machines was nearly 42 minutes.Upon reviewing the data in Vendon Cloud, we identified a recurring alert event labeled “Door open.”After discussing this data pattern with our Customer and facility managers, we discovered that the doors have had issues for some time. However, no one had reported the problem and everyone just continued with their daily routine.

Note: Vendon Cloud sends real-time notifications (depending on the machine) when stock levels reach a critical point, enabling to efficiently plan refill routes with precise quantities of components for each coffee machine.

Through insights gathered from the Downtime report and Refill report, our Customer successfully revamped their refill procedure. We slashed average downtime from 42 to 12 minutes — an impressive reduction of 71.4%. Furthermore, this optimization translates into substantial time savings visiting coffee machines only when necessary by employees of facility management who are responsible for cleaning and refills.

Note: Vendon Cloud sends real-time notifications (depending on the machine) when stock levels reach a critical point, enabling to efficiently plan refill routes with precise quantities of components for each coffee machine.

Through insights gathered from the Downtime report and Refill report, our Customer successfully revamped their refill procedure. We slashed average downtime from 42 to 12 minutes — an impressive reduction of 71.4%. Furthermore, this optimization translates into substantial time savings visiting coffee machines only when necessary by employees of facility management who are responsible for cleaning and refills.

Avoiding Waste

Now, let’s jump into the gained outcome when analyzing Component Usage! Our goal here was to assist our client in comparing the ordered quantities of ingredients with the actual amounts refilled in their machines.Imagine the impact on costs and sustainability! Upon further investigation, we discovered that the main issue was that facility managers were cleaning the machines during the lunch break, even if they had been refilled with fresh milk in the morning. Additionally, they often skipped the final cleaning at the end of the day. As a result, large amounts of milk:Our findings in just two months revealed a huge waste of nearly 680 liters of milk.

- went bad

- were simply poured down the sink because of the cleaning process.

A Red Flag for Coffee Machine Longevity and Coffee Taste

Analytics from Vendon Telemetry also highlighted issues with cleaning schedules. During the test period, we saw that 256 cleanings were done and 343 cleanings were missed.

Analytics from Vendon Telemetry also highlighted issues with cleaning schedules. During the test period, we saw that 256 cleanings were done and 343 cleanings were missed.

More than 50% of cleanings that were needed were skipped which led to frequent technical issues with machines and spoiled coffee taste because milk tubes were dirty and milk went bad.Additionally, the cleaning schedules were not coordinated with refilling times and peak demand periods. This often resulted in cleaning being done during the busiest times.

Analyzing Consumption Patterns & Optimizing Refills

Another significant example is the Refill report and its role in identifying and addressing inefficient and not planned refill schedules. Previously, machines were refilled about 4 times a day not depending on any data or consumption patterns. Based on analytics of consumption, Vendon proposed a new schedule for cleaning and refilling – coffee machines have to be at full service during morning peak time and during the day, so it’s best to fully refill and clean coffee machines at 5-6 PM. We also suggested implementing the Vendon Mobile for every refill, enabling precise tracking of ingredient usage by adding the exact amount each time. Additionally, upgrading the sizes of milk and coffee containers to align with average consumption was proposed so there is no need to visit and refill the machine more than once.

Another insight provided by component usage analytics was the ability to monitor peak hours – coffee consumption periods throughout the day as well as the choice of drink. Additionally, one of the findings our Customer found was that the newly introduced oat milk option was a frequent choice amongst milk alternatives. As a reminder, one of the main goals of this pilot test was to test consumption of newly introduced ingredients, particularly to confirm if the demand (in this case, oat milk) from employees is indeed significant.

We also suggested implementing the Vendon Mobile for every refill, enabling precise tracking of ingredient usage by adding the exact amount each time. Additionally, upgrading the sizes of milk and coffee containers to align with average consumption was proposed so there is no need to visit and refill the machine more than once.

Another insight provided by component usage analytics was the ability to monitor peak hours – coffee consumption periods throughout the day as well as the choice of drink. Additionally, one of the findings our Customer found was that the newly introduced oat milk option was a frequent choice amongst milk alternatives. As a reminder, one of the main goals of this pilot test was to test consumption of newly introduced ingredients, particularly to confirm if the demand (in this case, oat milk) from employees is indeed significant.

Coffee Inconsistency and Implementing Automatic Ordering

An analysis comparing coffee consumption to the quantity refilled using an app everytime unveiled a significant gap: almost 70 kilograms of coffee seemed to be missing. This discrepancy arose from frequent, small refills throughout the day. Furthermore, Vendon empowered them to track average consumption patterns and fine-tune their replenishment quantities accordingly. Additionally,Vendon OCS Warehouse solution facilitated the tracking of total stock available in all warehouses. Moreover, Vendon Mobile enabled the precise recording of amounts added at the machine, streamlining the entire reconciliation process and eliminating the risk of human errors associated with manual counting. Additionally, the Customer is currently testing and planning to implement automatic ordering based on average component usage.

What We Learned?

This case study stands as a real learning lesson of how data-driven solutions can have an undeniable impact on optimizing operations and cost savings. The Customer gained insights that proved the value and transparency that telemetry gives:- Downtime Report and Event Alers helped to slash down average downtime by 71.4% decreasing it from 42 to 12 minutes;

- Data analysis of Component Usage and Cleaning Events found that nearly 680 liters of milk were wasted due to improper cleaning and refilling processes of facility management;

- The Refill Report showed that machines were refilled about four times daily, without considering data or consumption patterns. Vendon proposed a new schedule: fully service coffee machines during morning peak times and again at 5-6 PM;

- Cleaning Reports revealed that over 50% of necessary cleanings were skipped, with 256 cleanings completed and 343 missed, thus directly impacting the overall machine technical status and longevity;

- Due to frequent, small refills throughout the day, almost 70 kilograms of coffee appeared to be missing. Vendon empowered them to track consumption patterns and adjust replenishment using Vendon OCS Warehouse and Vendon Mobile solutions.