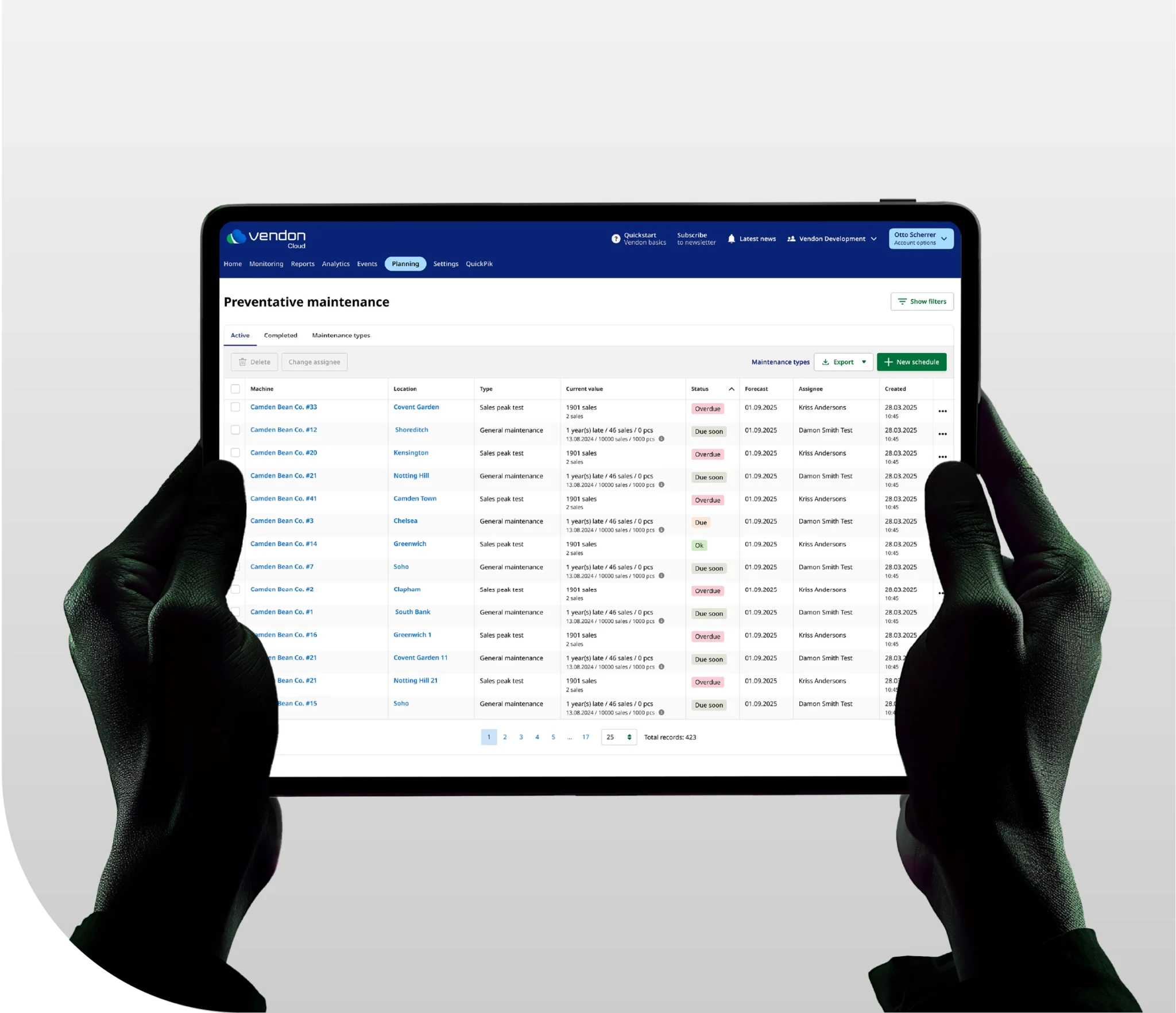

Preventative maintenance

Use machine data to plan maintenance, reduce breakdowns, and extend the lifespan of machines across mixed fleets.

50% less downtime

Preventative maintenance uses real-time machine data and manufacturer-recommended service intervals (added by users) to predict issues and schedule service before failures happen.

- Know exactly when grinders, filters, and milk systems need attention

- Get automatic alerts before parts wear out or expire

- Track all upcoming and completed tasks in Vendon Cloud

See the signs before the breakdown

When managing a fleet of machines, it’s hard to know what might fail next.

Track brewing time, water flow, and temperature in real time. Know what’s happening in each café—even when you’re not there.

Why preventative maintenance is worth it

Machines last longer

With Vendon Cloud, service is scheduled based on actual usage, not fixed intervals. That means you only maintain what’s necessary — keeping machines in better condition, reducing wear, and extending their overall lifespan.

Minimized downtime

Vendon Cloud constantly monitors machine performance and sends alerts when something starts to go off — like a slow motor or temperature fluctuation. Step in early, reduce unplanned breakdowns, and keep sales and service running smoothly.

Proactive care

Track the usage of key components — like grinders, filters, and milk systems — based on real-time machine data. Get notified when replacements are due, avoid failures, and plan spare part stock in advance.

Lower maintenance costs

Catch small problems before they become big ones. Vendon Cloud identifies unusual patterns, helping you avoid urgent repairs and unnecessary technician visits. Fewer surprises, better control over your maintenance budget.

Better use of energy and resources

Well-maintained machines run more efficiently and waste less. Reduce energy use and avoid overworking equipment. Proactive care leads to a smarter, more sustainable operation.

Aim for zero-downtime service

Trust starts with reliability — and regular maintenance makes it possible.

When your machines run smoothly, your clients don’t have to think about them. That’s exactly how it should be. Consistent coffee and service quality keep customers satisfied and partnerships strong.

Ideal for:

Vending operators

Manage large, mixed fleets easily with our IoT connectivity — this is where we excel. Offer the best payment method for each location — from cash and mobile to closed-loop solutions.

OCS operators & Coffee roasters

Manage all your coffee machines effectively from one platform. Use real-time data to monitor consumption, coffee quality, and ensure contractual obligations are met.

HORECA & retail

Fast, reliable payments and IoT connectivity — perfect for hospitality and retail businesses looking for effective solutions and remote control of machines and employee performance.