Office coffee service (OCS) businesses are among the hardest hit by the pandemic. With millions of people switching to remote work, many offices now sit empty. Plus, recent surveys suggest that no matter what happens with the pandemic, a significant part of the workforce will continue to work remotely in the future in some capacity.

Pair this with increased attention to hygiene and weariness to use shared items, machinery, and even spaces, and the immediate outlook for OCS businesses is bleak. Some industry estimates suggest that it will take years for the industry to recover to its pre-COVID-19 levels.

This is a shame since OCS and self-service are among the fastest-developing and most exciting segments.

However, many OCS operators are at a critical juncture in their business endeavors. Optimization and cost-cutting are urgently needed for businesses to survive, highlighting the importance of IoT solutions now more than ever. As an OCS business owner, you should do everything in your power to adapt to this new reality and be ready to weather it for months to come.

Let’s talk about 5 ways how you can do exactly that.

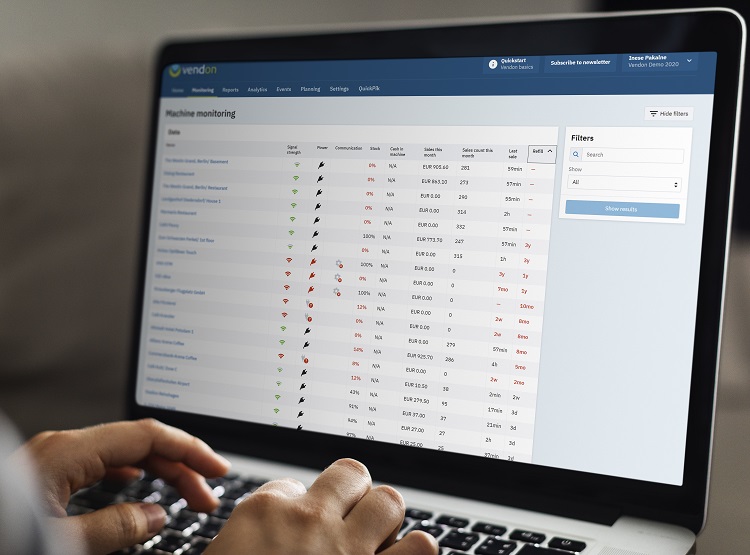

Thousands of vending and coffee businesses rely on Vendon’s IoT solutions to provide them with actionable data that helps minimize business expenses and optimize performance. From saving on unnecessary trips through real-time reports to ensuring adequate and timely machine maintenance for asset longevity, here’s how to optimize an OCS business with IoT.

1. Tracking consumption remotely for correct and automated invoicing

For OCS operators running a pay-per-cup or revenue-share business model, invoicing can be a time- and resource-consuming process, particularly for those of you with large fleets. To issue an invoice, usually, someone from the operator’s team must travel to the machine and collect data from the counters.

However, it can feel like an unnecessary visit if the machine is in technical order and functioning well. As a result, business owners incur travel and labor costs just for the invoicing process. Plus, manual data collection runs the risk of human error.

Vendon’s IoT solution helps you collect this data remotely and digitize this process, ensuring correct invoicing for the number of cups dispensed thanks to accurate and detailed reports. You can track drinks consumption in your Vendon Cloud dashboard and, when the invoicing day comes around, generating a detailed report takes a single click. Invoicing can be automated even further by automatically sending data from the Vendon system to the operator’s ERP, where invoices are generated. This lets you completely eliminate unnecessary visits, significantly reduce labor and travel expenses, collect correct data, and automate your invoicing.

2. Using the right machines for each location

If a machine’s capacity is too large for a location, it’s being underused in terms of drinks made. Similarly, a machine that’s too small and can’t meet demand is going to result in lost income and poor customer experience.

With the pandemic affecting consumption patterns, chances are that your fleet is no longer optimized for each location. It’s vital to utilize machines that best match sales volumes to guarantee optimal revenue flow and to do that OCS operators need to compare machine capacity with sales for each location.

Vendon lets you easily track the actual number of drinks dispensed daily for each machine, which provides you with the essential insights to make correct decisions regarding machine placement. With offices empty, having a machine sit underused is one of the most common issues faced by operators, but you don’t have to be one of them.

3. Tracking cups made vs beans sold

The main risk faced by operators running a pay-per-ingredient model is when the clients source their own ingredients. Since you’re renting out a machine free of charge and only bill clients for the ingredients used, clients sneaking in their own beans to minimize costs can seriously affect your revenue. This is a particularly acute problem during the pandemic, as businesses try to cut costs at every corner.

Without any IoT solutions in place, it can be difficult for operators to actually know that it’s happening.

Vendon enables operators to track the number of cups made and compare this number to coffee bean sales to ensure beans are not sourced from elsewhere. This allows operators to ensure their business is running at full capacity and helps avoid lost revenue at a time when every penny counts.

4. Monitoring machine maintenance

For OCS businesses hit by the pandemic, it’s important to get maximum profit from every machine. Since each machine is a significant investment, ensuring longevity is key for long-term profitability and can be achieved through proper cleaning and maintenance.

Typically, the customer is responsible for cleaning the machine, as it must be done at regular intervals, making it unviable for the operator to take care of it. Unfortunately, customers often fail to observe proper and timely cleaning practices, negatively affecting the length of the machine’s lifetime and costing the operator in maintenance and machine replacement. On top of that, inadequate maintenance can affect product taste and even scare away potential sales, resulting in dissatisfied customers and further losses.

Vendon empowers operators with information about when and for how long a machine is cleaned and allows for enforcing proper maintenance practices with customers. This extends machine’s lifetime, reduces operator maintenance visits, and ensures good drink quality, which leads to higher revenue.

5. Ensure contactless payments and offer a loyalty app

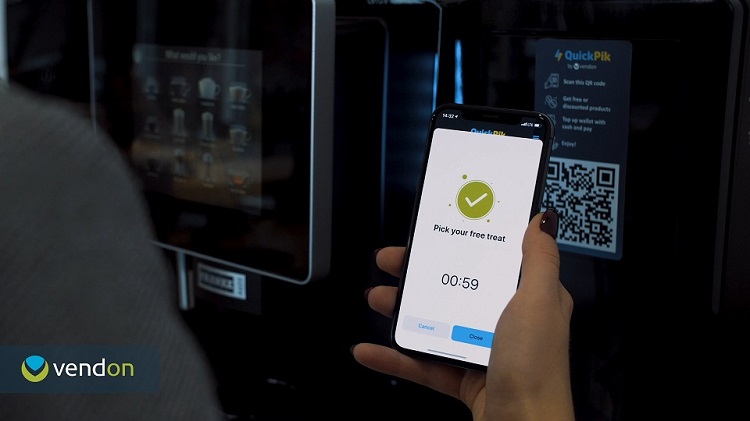

Providing a variety of payment solutions has always been key to ensuring as many people as possible can use your coffee machine, however, offering contactless payments is now more important than ever, as people are reluctant to touch common surfaces and employers enact hygiene policies to make the work environment safer.

Furthermore, you can integrate and introduce your clients to QuickPik – Vendon’s loyalty platform and mobile payment app for employees. With most businesses seeking to cut costs as much as possible, this digital solution enables employers to limit consumption by assigning fixed amounts of free coffee cups per day, week, or month to various employees or employee groups. Employees get free or discounted beverages just by scanning a QR code with their phones. With options to set discounts and create a variety of bonus schemes for different employee groups, this is a solution that is highly appealing to the pandemic-affected business.

Even for those OCS businesses operating under a pay-per-ingredient model – QuickPik can be a key selling point when in talks with a new customer.

Conclusion

These are just 5 specific ways how to optimize an OCS business with IoT. There are many more. From adapting to customer preference changes (did you know that sales for chocolate have significantly increased during the pandemic?) to changing drink prices remotely – IoT solutions give operators the tools and data they need to keep their coffee business profitable.

The main benefits of Vendon’s IoT solution for coffee businesses are offering a digital overview of their entire fleet in one platform and ensuring access to the real-time data that helps make the best decision in any scenario, all of this in addition to enabling 2-way communication and remote management of machines.

By taking proactive and optimization-driven action, OCS operators can significantly minimize the pandemic’s impact on their business. What’s more, all signs point to a strong industry bounce-back in the coming years. Until then, Vendon will help with cutting costs and ensuring efficient business performance.

Start optimizing your coffee business today and boost your revenue – get in touch with us at grow@vendon.net or your local distributor.