Identified as an untapped gem within Vendon Cloud, our OCS Warehouse tool has recently undergone a complete makeover making it more user-friendly than ever. The update was driven by our commitment to ensuring that Vendon Cloud is easy to use and brings value to coffee customers.

In the dynamic world of office coffee services, managing stock levels efficiently can be a challenging task. Although telemetry is needed for both vending and coffee machines, OCS businesses require different functionalities. Things like, refill package size, no maximum value, and tracking stock for the customer warehouse (or location), are all extremely important when you have a coffee-operating business.

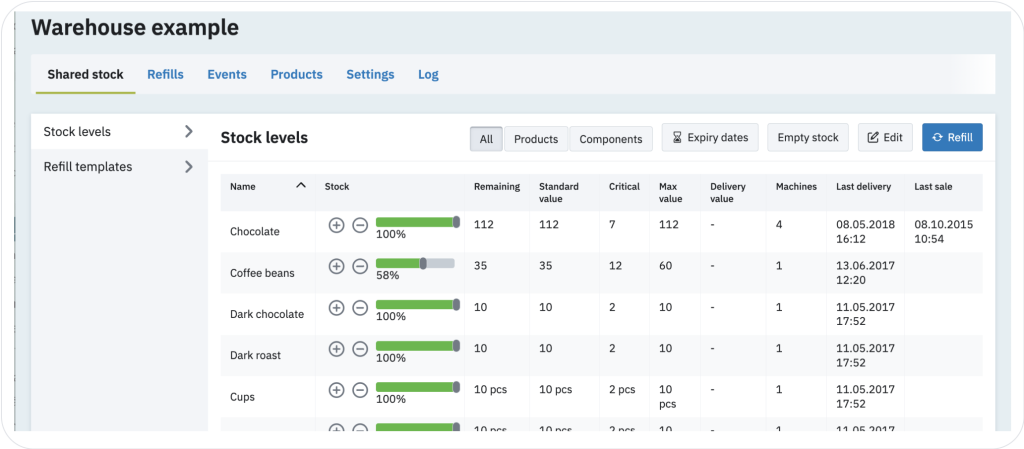

The OCS Warehouse tool facilitates the management of stock levels at a customer’s warehouse level, enabling operators to oversee and control stock based on location rather than individual machines. For instance, if you operate a coffee business with a pay-per-bean model and have multiple coffee machines spread across different client locations, you would want to monitor the overall stock in each warehouse or location, rather than focusing on the ingredient stock in each individual machine. Thus allowing you to not only effectively manage stock and refill routes but also see if customers aren’t placing their own beans.

Main Pain Points we address with OCS Warehouse tool:

1. Maintain consistent deliveries with the correct amount of product or components

Over-delivery may lead to excess inventory and storage problems for the customer, while under-delivery can cause stockouts and disruptions in operations. Striking the right balance ensures efficiency and customer satisfaction. We help to manage stock on a “customer warehouse level” where the customer is the one to fill the machine, but the operator delivers the right amount of product / components to the location.

2. Lack of transparency or control over the sourcing of coffee beans used by the location

In the pay-per-bean model for OCS businesses, challenges arise from limited control over coffee bean usage at client locations, leading to potential issues like inconsistent quality, fraudulent activity, billing discrepancies, and customer dissatisfaction. We help to oversee the stock at the warehouse and compare it with consumption patterns across all machines.

3. Inefficient routes

Planning routes for OCS machines can be complex due to the need to accommodate stock beyond the machine’s capacity. We help to plan routes for OCS businesses based on stock at warehouse level not machine level.

New Features of the OCS Warehouse

For those acquainted with OCS Warehouse tools, you’ll be pleased to learn that we’ve not only enhanced the design and usability but also incorporated several highly requested features from our clients, making them even more valuable. Here are a few highlights of these enhancements:

- The Warehouse Account section now offers easy access to all warehouse information and settings.

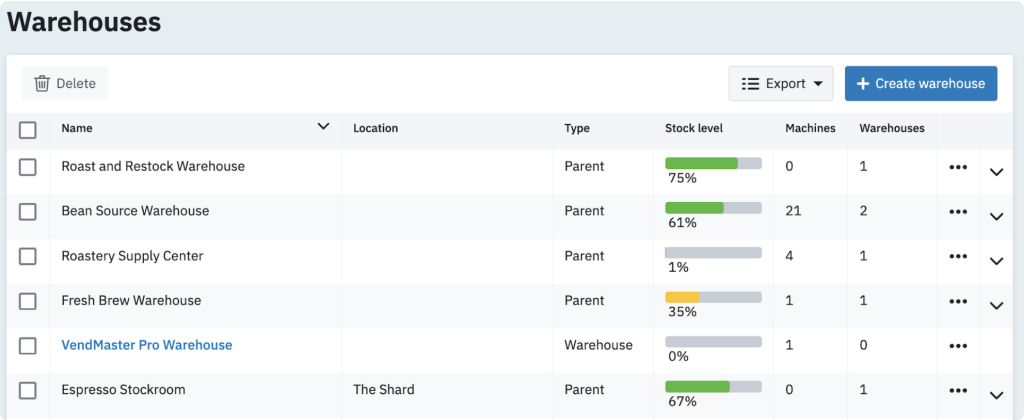

- We have added a “Parent Warehouses” feature that allows operators to group multiple warehouses under one main warehouse. While the stock is still managed at the individual warehouse level, the Warehouse list now displays the average stock level for all machine warehouses under the Parent warehouse. Sub-warehouses have been replaced by this more intuitive Parent warehouse system.

- Introducing the “Allow Overstock” option to refill products beyond 100% of the standard stock value. By enabling overstock, the need for adjusting the Maximum value with every refill is eliminated, providing a time-saving solution for clients.

- “No Stock Sale Evens” feature is designed to address issues related to incorrect stock management or fraudulent activity with components. This event is generated when a machine associated with a warehouse sells a product that is currently at 0% stock in the warehouse.

Similar to Refill unit size, “Packaging Size” represents the amount of stock in one package to be refilled. Users will now see a warning if the standard amount to refill cannot be divided by the packaging size.

How to start using the OCS Warehouse tool

For existing Vendon Cloud users, adopting OCS Warehouse is a breeze. Users simply need to create warehouses and add their existing or new machines to these centralized locations. If a machine is already integrated into the Vendon Cloud with specific products, the transition to tracking stock levels in the warehouse is seamless – all products from that machine are automatically transferred to the shared warehouse stock.

What solutions do we offer for OCS operators?

Using Telemetry can be highly beneficial for OCS businesses for various reasons, such as tracking sales and consumption as well as keeping up with maintenance and warehouse management. Read on to find out about the main tools that you can utilize for optimizing your OCS business.

- Rapports de nettoyage

- Downtime report

- Maintenance préventive

- Temperature sensor

- Modifications de prix à distance

- Stock Control & Route Planning

- Sales Report

- Component Usage tracking

| Solution | Description |

|---|---|

| Rapports de nettoyage | Regular cleaning is an essential part of maintaining not only a top-notch technical condition of your machines but it can also affect the taste of the coffee. With Cleaning Reports, you can keep an eye on your machines, tracking and following up the cleaning processes with instant real-time data. Cleaning goes hand-in-hand with the maintenance of your machines - each minute when your machine isn't working properly, can lead to lost sales and revenue. |

| Rapports d’arrêts | Additionally, with our Downtime Reports, you can see lost sales and revenue during the machine's downtime which can help you keep track of your financial situation in real-time and take action immediately. Vendon downtime reports also have the functionality of alerting you of any technical issues arising in real time to let you start dealing with them quickly, avoiding calls from unhappy customers. Preventative Maintenance |

| Maintenance préventive | With a centralized tool like Preventative Maintenance which lets you schedule and track maintenance works, you can easily plan and allocate resources, stay informed about ongoing tasks, and maintain accurate records of maintenance activities. |

| Temperature Sensor | At Vendon, we truly believe in the importance of the taste and quality of good coffee, which is exactly why solutions such as the Temperature Sensor can be very helpful. Operators can monitor milk and water temperatures remotely and react quickly if something goes awry, thereby providing the best possible customer experience with delicious coffee. |

| Modifications de prix à distance | Vendon remote coffee machine management solution brings more functionalities, for example - Remote Price Change. This option allows effective use of resources and saves unnecessary visit costs. |

| Stock Control | Vendon Telemetry can help you optimize your operations even further with Stock Control. in Vendon Cloud, stock levels of all machines are visible in real-time and you will always know which products are necessary to bring for the refill. |

| Route Planning | With Vendon, you can save up to 40% on routing costs by using Route Planning to plan trips beforehand and visiting only those machines that require filling or repair. |

| Automated Sales Report | Another great tool for OCS operators is the Automated Sales Report. This solution provides a detailed overview of transactions, location, or product performance, and allows you to analyze consumption patterns, best selling products, and underperforming machines. |

| Component Usage | For operators whose main income stream is ingredients, it is crucial to track if the machine contains the necessary products used for making the drinks. Otherwise, ingredients bought elsewhere due to price or taste are lost income and potentially lost account. To avoid this, you can track Component Usage through Vendon Cloud. |

Explore all Vendon solutions for OCS businesses here.

To sum up

Vendon’s newest OCS Warehouse update is an important step toward supporting our OCS clients to optimize their business by simplifying everyday operations. By addressing the specific challenges faced by OCS businesses, we aim to not only enhance the overall efficiency of coffee machine management but also deliver tailored and adaptable solutions to our clients, making their day-to-day easier.

For OCS operators, taking care of coffee machines can be very crucial to not only the longevity of the machines but also customer satisfaction and overall business efficiency. Telemetry can be a game changer for any coffee business as it keeps you up to date with everything that’s going on with your machines in real time and allows you to manage them remotely. With Vendon, you also get detailed overviews of sales, consumption, machine performance, and other analytics tools.