Connectivity for perfect brew, every time

Access real-time data and remotely monitor all your traditional espresso machines, ensuring consistency and coffee quality with our IoT solution.

Discover new possibilities

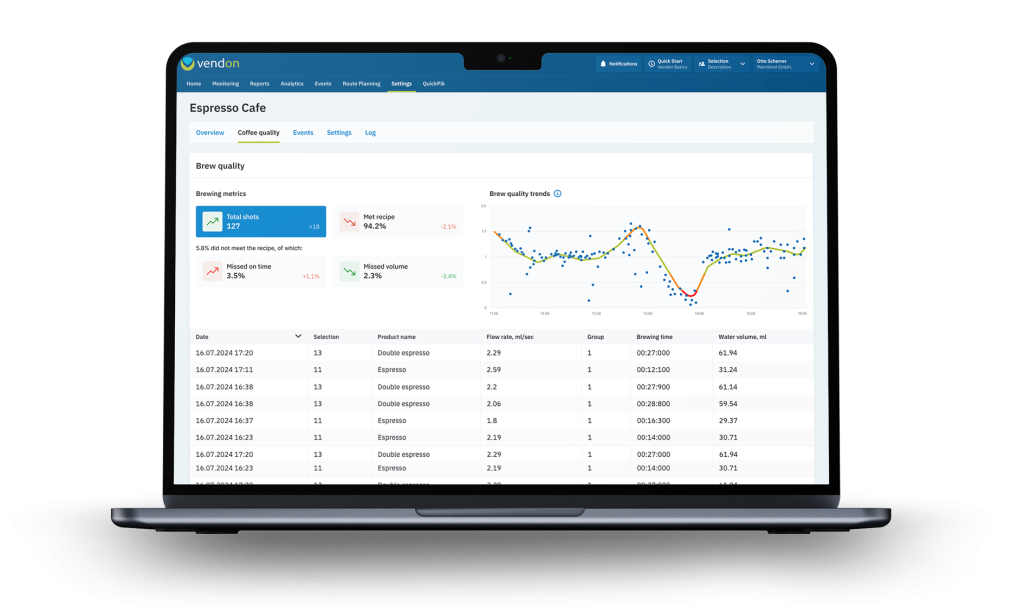

With Vendon Cloud, a real-time, cloud-based IoT analytics software, you can access critical data about your machines, including component usage, maintenance, and coffee quality. This solution enables you to optimise operations, enhance service quality, and ensure consistent drink quality.

How the solution works

The solution centers around an IoT device, vBox, now enhanced with the latest addition, BaristaBox. Both devices seamlessly connect to coffee machines, transmitting data to Vendon Cloud.

This integration empowers operators to efficiently monitor and manage all their machines through a user-friendly platform that offers valuable insights and comprehensive reports.

Universal compatibility

Vendon’s connectivity solution supports all brands of traditional espresso machines and superautomatic coffee machines, allowing operators to manage their entire fleet through a unified platform.

Business efficiency enabled by data

Ingredient usage tracking

Track cups dispensed remotely, helping you identify inconsistencies.

Drink quality

Track water flow rate and brewing time to ensure recipe accuracy.

Preventative maintenance

Monitor machine performance for proactive maintenance.

Cleaning reports

Access detailed cleaning data to ensure machines are well-maintained.

Our coffee IoT solution brings value to

- Coffee shop owners

- HoReCa chains

- Coffee roasters & distributors

- Coffee machine manufacturers

Use Cases

Ensuring coffee quality

Enforcing contractual obligations